Standard Operating Procedure (SOP) for [Specific Process or Activity]

SOP Standard Operating Procedure Vector Isolated. Abbreviation Royalty - Source cartoondealer.com

Key Takeaways:

| Key Difference | Description |

|---|---|

| Standardization | SOPs establish uniform processes and procedures, eliminating variations and ensuring consistency. |

| Quality Control | SOPs define best practices, reducing errors and maintaining high-quality standards. |

| Efficiency and Productivity | By streamlining processes, SOPs improve efficiency and increase productivity. |

| Compliance | SOPs help organizations meet regulatory requirements and industry standards. |

...[Continue with the main article topics]...

FAQ

This section addresses commonly asked questions regarding the Standard Operating Procedure (SOP) For [Specific Process Or Activity]. It provides detailed explanations to address any concerns or misconceptions.

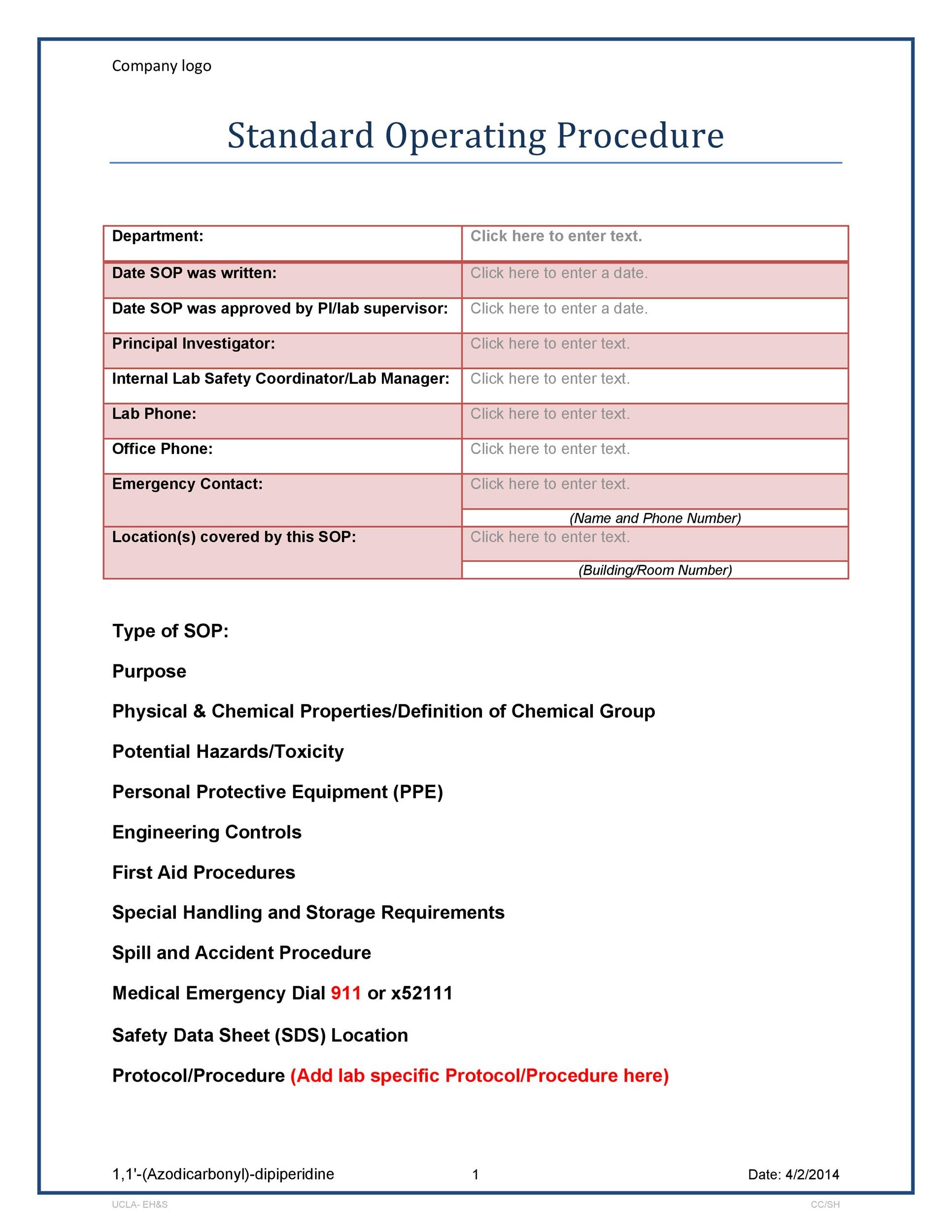

How To Write A Standard Operating - Source utaheducationfacts.com

Question 1: What are the specific steps involved in implementing the SOP?

The SOP outlines a comprehensive set of instructions and guidelines that should be followed step-by-step. Refer to the SOP document for a detailed breakdown of each step.

Question 2: What are the potential risks associated with not following the SOP?

Adherence to the SOP is crucial to ensure compliance, safety, and operational efficiency. Failure to follow the SOP may result in errors, accidents, or suboptimal outcomes.

Question 3: How often should the SOP be reviewed and updated?

Regular review and updates are essential to maintain the effectiveness of the SOP. The frequency of review should be determined based on factors such as regulatory changes, technological advancements, or emerging best practices.

Question 4: Who is responsible for ensuring that the SOP is followed?

Clearly defined roles and responsibilities are critical. The SOP should specify the individuals or teams responsible for implementation, monitoring, and enforcement.

Question 5: What are the consequences of non-compliance with the SOP?

The SOP should outline appropriate consequences for non-compliance. These consequences may vary depending on the severity of the infraction and the impact on operations.

Question 6: How does the SOP align with industry standards and best practices?

The SOP should be developed in accordance with relevant industry standards, regulations, and best practices. This ensures that the organization operates in a compliant and efficient manner.

By addressing these common questions, this FAQ section provides a comprehensive overview of the importance and implementation of the Standard Operating Procedure (SOP).

Return to Standard Operating Procedure (SOP) For [Specific Process Or Activity].

Tips for Standard Operating Procedure (SOP)

Standard operating procedures (SOPs) are a critical part of any quality management system. They provide clear, step-by-step instructions for employees to follow, ensuring that processes are carried out consistently and efficiently. By following these tips, you can create SOPs that are effective and easy to use.

Tip 1: Define the purpose and scope of the SOP.

The first step in creating an SOP is to define its purpose and scope. This will help you determine what information to include and how to structure the SOP.

For example, an SOP for a manufacturing process might include instructions on how to operate the equipment, how to inspect the products, and how to handle waste.

Tip 2: Use clear and concise language.

SOPs should be written in clear and concise language that is easy to understand. Avoid using technical jargon or slang.

For example, instead of writing "The operator shall calibrate the equipment," write "The operator shall turn the calibration knob until the needle points to zero."

Tip 3: Include visuals.

Visuals can help to make SOPs more user-friendly and easier to understand. Consider including diagrams, flowcharts, and pictures.

For example, an SOP for a cleaning process might include a diagram of the cleaning area.

Tip 4: Get feedback from users.

Once you have created an SOP, it is important to get feedback from users. This will help you identify any areas that need to be improved.

For example, you might ask employees to review the SOP and provide feedback on its clarity and usefulness.

Tip 5: Keep SOPs up to date.

SOPs should be reviewed and updated regularly to ensure that they are accurate and current. Changes in processes, equipment, or regulations may require updates to SOPs.

For example, if a new piece of equipment is installed, the SOP for the process that uses the equipment may need to be updated.

Conclusion

By following these tips, you can create SOPs that are effective and easy to use. SOPs can help to improve quality, efficiency, and safety in any organization.

Standard Operating Procedure (SOP) for [Specific Process or Activity]

A Standard Operating Procedure (SOP) for a specific process or activity is a critical framework that outlines the step-by-step instructions, roles, and responsibilities involved in executing a task efficiently and consistently. It serves as a roadmap, ensuring compliance with regulations, maintaining quality standards, and minimizing risks.

- Documentation: Clear and concise documentation of the SOP is essential for easy access and understanding.

- Training: Training and education programs ensure that personnel are adequately prepared to follow the SOP.

- Monitoring: Regular monitoring and review of the SOP's effectiveness help identify and address any necessary revisions.

- Compliance: Adherence to the SOP ensures consistent execution of tasks, regulatory compliance, and quality control.

- Safety: SOPs prioritize safety measures, minimizing risks and ensuring a safe work environment.

- Continuous Improvement: Regular evaluation and feedback mechanisms enable continuous improvement of the SOP.

Human Resources Sop Template - Source templates.rjuuc.edu.np

For instance, an SOP for a laboratory safety protocol outlines specific steps for handling hazardous materials, using equipment, and responding to emergencies. It ensures that experiments are conducted safely, minimizing risks to personnel and the environment.

Standard Operating Procedure (SOP) For [Specific Process Or Activity]

Standard Operating Procedures (SOPs) are critical for ensuring consistent and efficient execution of processes and activities within an organization. They provide detailed instructions on how to perform specific tasks, reducing the risk of errors and ensuring compliance with regulatory requirements. For any given process or activity, the corresponding SOP defines the steps to be followed, the materials and equipment required, and the responsibilities of personnel involved. By adhering to these SOPs, organizations can maintain high standards of quality, safety, and efficiency.

Sop For Inventory Management Template - Source templates.rjuuc.edu.np

SOPs play a vital role in various industries, including manufacturing, healthcare, and business operations. In manufacturing, SOPs ensure the consistent production of high-quality products by standardizing processes and minimizing deviations. In healthcare, SOPs are crucial for patient safety and regulatory compliance, outlining best practices for medical procedures and handling of sensitive information. In business operations, SOPs streamline workflows, improve communication, and reduce the risk of operational errors.

To be effective, SOPs should be clear, concise, and easily accessible to all relevant personnel. They should be regularly reviewed and updated to reflect changes in processes or regulations. By maintaining and enforcing SOPs, organizations can enhance their overall performance, reduce risk, and achieve operational excellence.

Conclusion

Standard Operating Procedures (SOPs) are indispensable tools for organizations seeking to achieve operational excellence. By providing detailed instructions for specific processes and activities, SOPs ensure consistency, efficiency, and compliance. As organizations embrace continuous improvement, it is crucial to regularly review and update SOPs to reflect evolving best practices and regulatory requirements. The effective implementation of SOPs empowers organizations to operate seamlessly, minimize risks, and deliver exceptional results.

The benefits of SOPs extend beyond individual processes and activities. By fostering a culture of standardization and discipline, SOPs contribute to a more cohesive and efficient work environment. They facilitate knowledge sharing, reduce the need for constant supervision, and enable organizations to scale their operations more effectively. As organizations navigate the complexities of modern business, the adoption and adherence to SOPs will remain a cornerstone of operational success.